Chopped Strand Mat Plant

A CHOPPED STRAND MAT (CSM) Line produces Fiberglass MAT, which is one of the most popular forms of reinforcement for non-structural applications.

The CHOPPED STRAND MAT is a non-woven mat consisting of glass fibers laid randomly across each other and held together by a binder (emulsion or powder).

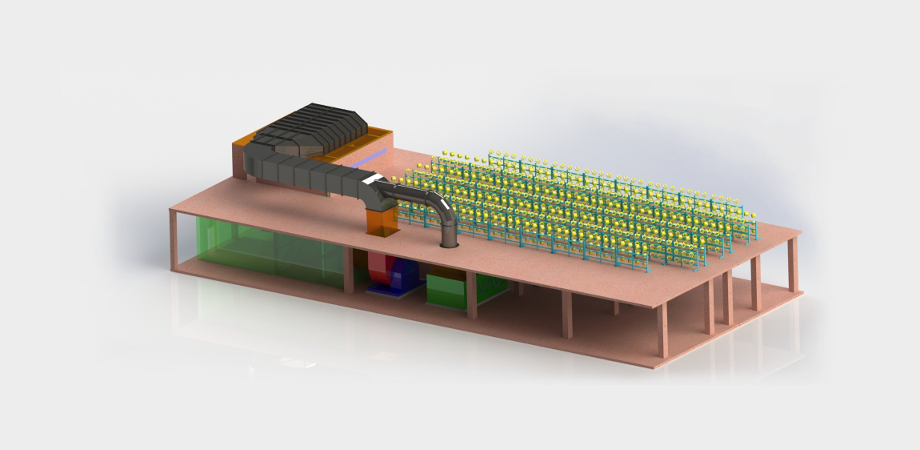

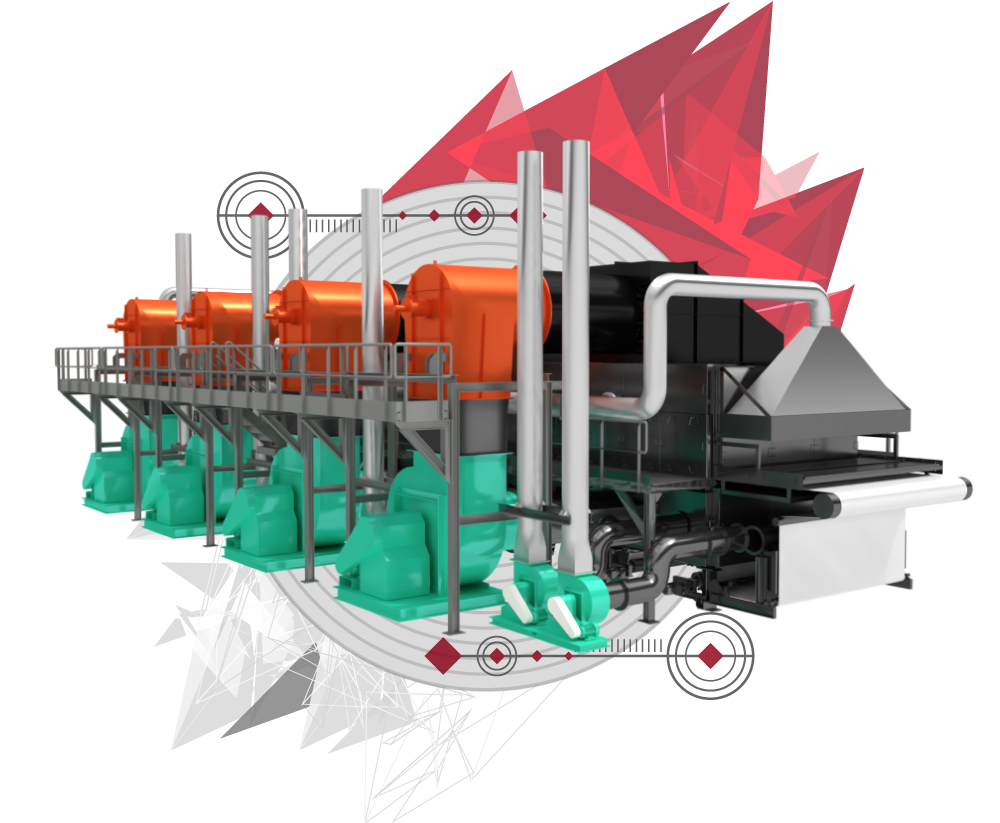

The “starting point” of the FIBERMECH’S CSM Line is the creel area, where the fiberglass cakes are located on the steel frames.

The strands are pulled and cut by the choppers and distributed in the forming chamber over a chain belt.

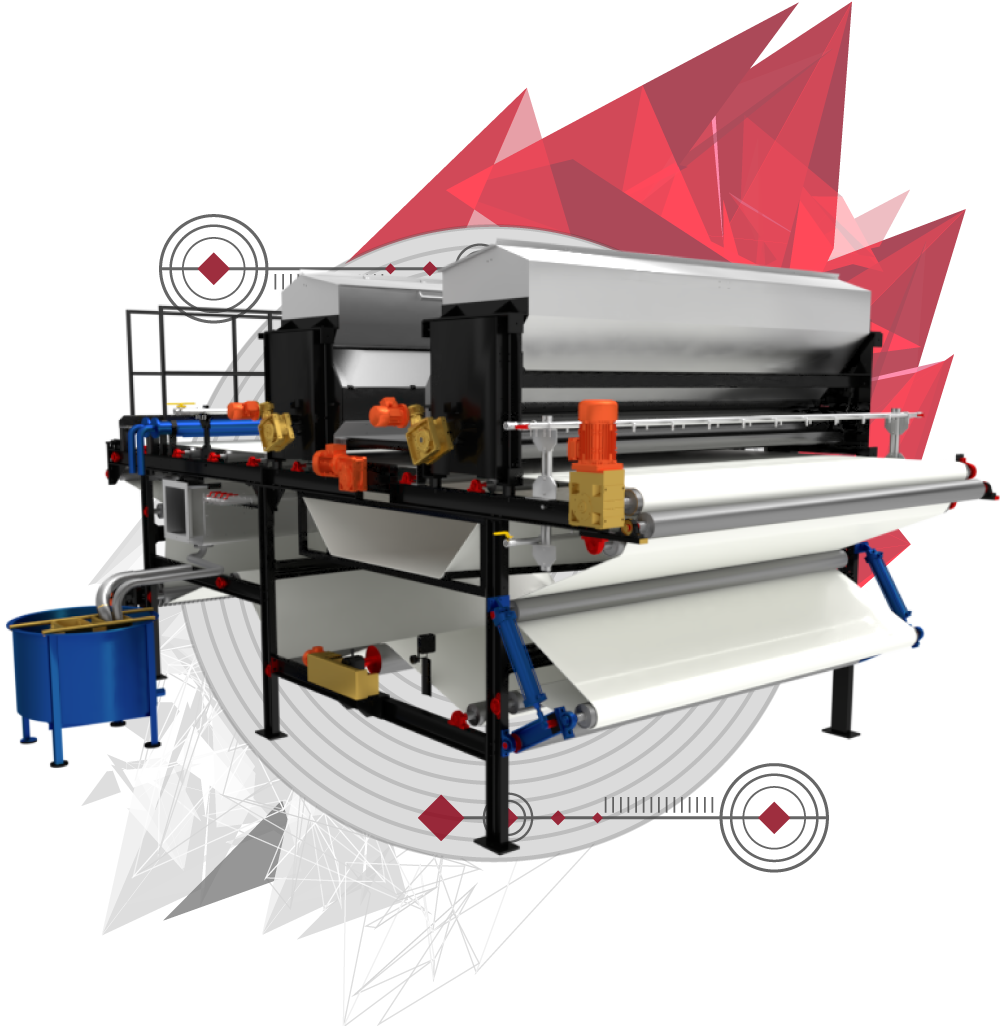

Subsequently the MAT is transferred by motorized chain belt from the forming to the bonding section where powder or emulsion binder is applied.

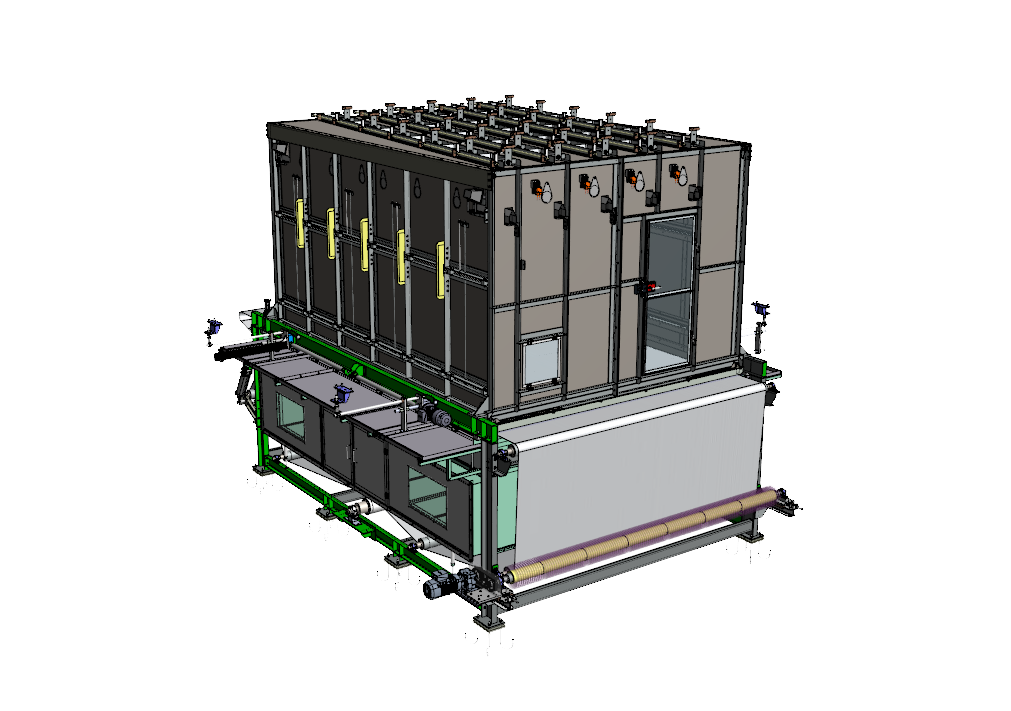

From the bonding section the product is transferred to the Drying and Polymerization section.

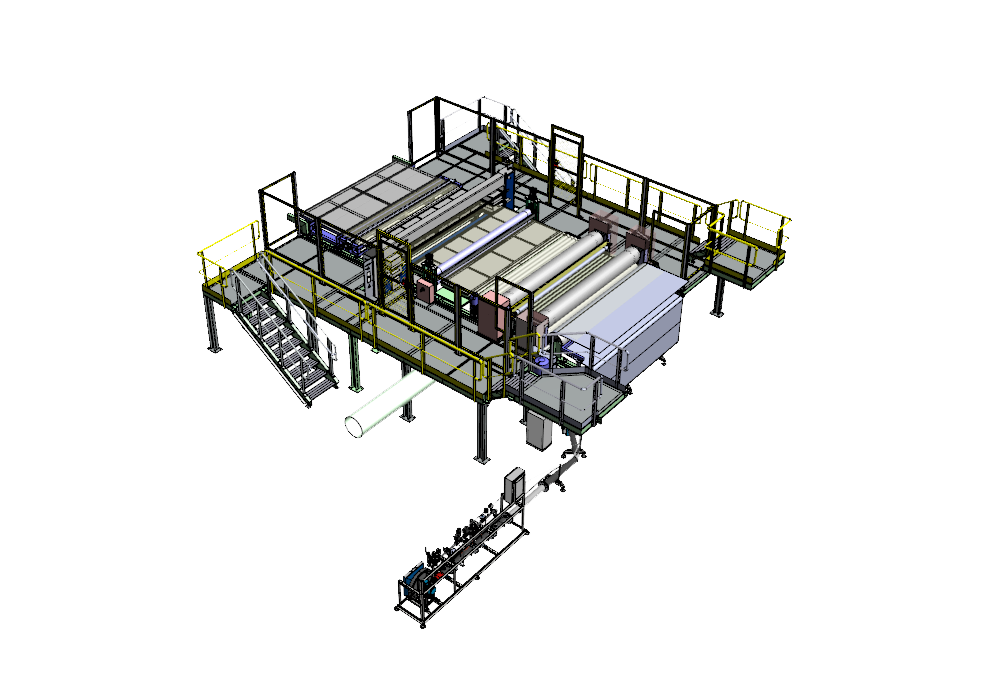

Then the product coming out from the oven is reaching the End Line.

The End line of the CSM line is composed by:

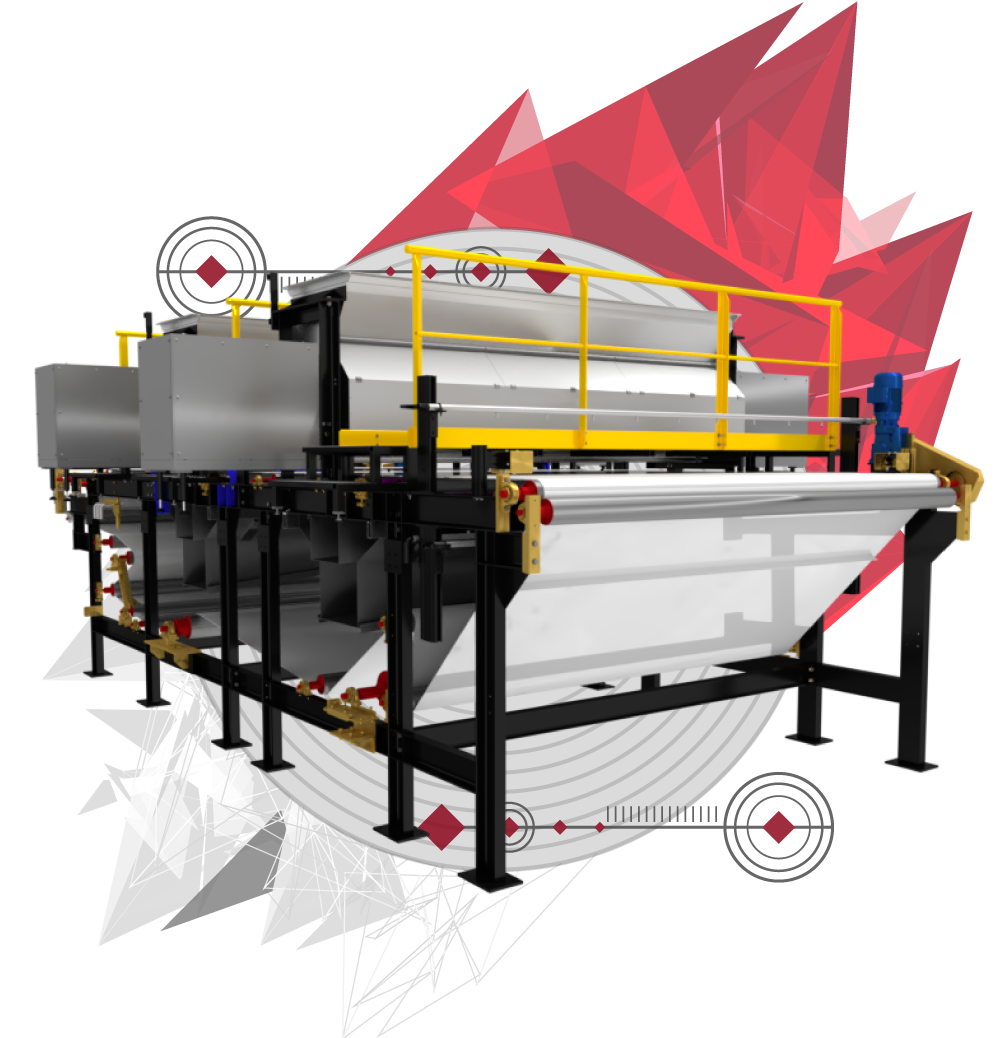

- The compact rollers and cooling section where the product is bonded and cooled down

- The quality and inspection system where all the parameters are verified

- The cutting and winding section where the MAT is trimmed, cut and wounde

The start up and the commissioning phases are always performed by senior level and experienced “fiberglass guys”.

According to customer requests, FIBERMECH is able to design the packaging line to be installed after the winding machine. The finished rolls after the winding phase are unloaded on the packaging line, where they are weighted, labelled and packed.

| Parameter | Units | Value |

| Line Speed | m/min | 0,5 ÷ 45 |

| Gross width | mm | 1500 ÷ 4000 |

| Weight per unit area | g/m2 | 100÷900 |